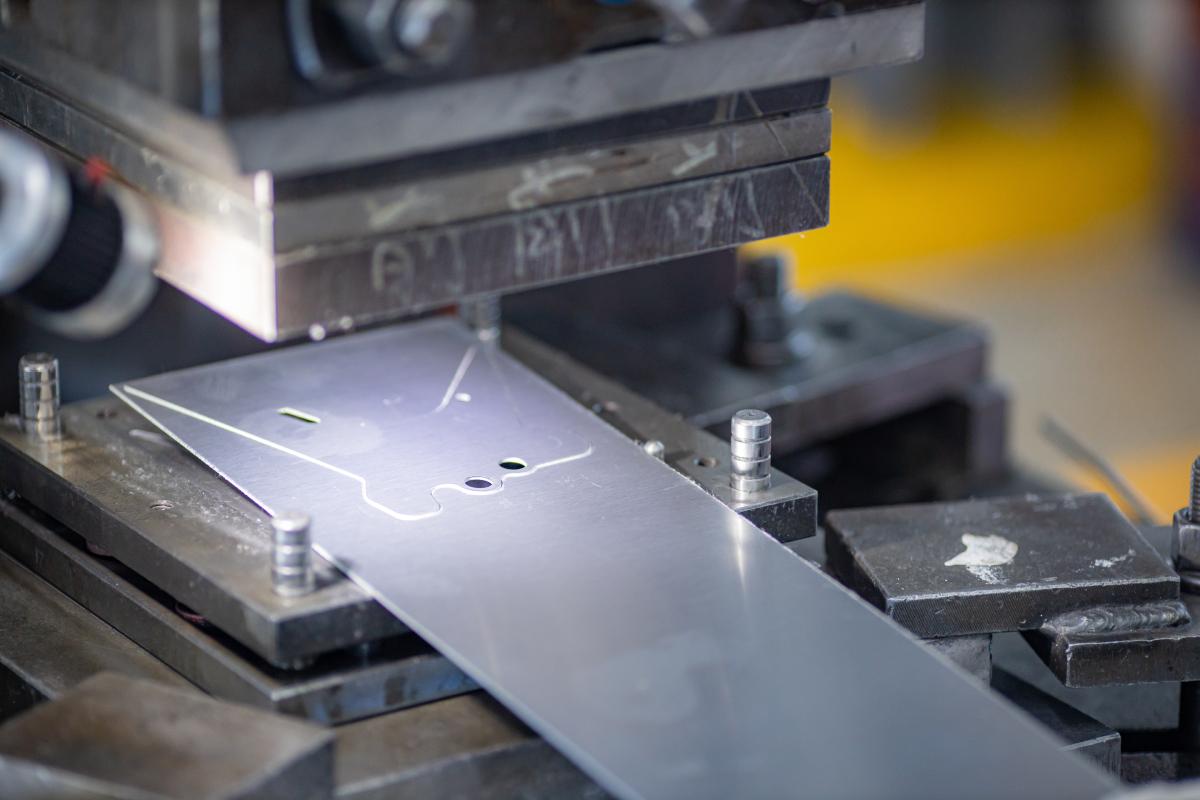

Cold forming allows us to manufacture a range of parts from small reinforcement parts to a much bigger parts. We operate presses in the range from 10 Tons up to 250 Tons. Consequently we are able to stamp light metal parts as well as sub assembly complex parts also we can stamp parts from 0.1mm up to 10mm and we also can manufacture in MS( D-EDD ), HR, SS , Spring Steels for both Two Wheeler as well as Four Wheelers.

At our shops we use the most advanced technologies for assembling much complex as well as smaller welding parts. We use Spot Welding and MIG- Welding for the strength of steel parts as required by the customer. Our welding cells are consist of Manual as well as Automated, We also use Programmable Robots to perform highly complex, severe, most precise welding’s. Thus we ensure highest quality in our assemblies.

Regarding Product Concept , Design & Cost Efficent Production

Submitting the lowest Quotation with highest quality ensured towards customer

Finalizing with the customer for the final approval/ PO

Submitting samples , conducting audits with customer representative to ensure the Customer satisfication and also get approvals

Parts will be delivered as per Customer Schedule / Requirement with proper packaging

After sales if any complaints or points were rasised by the customer it will be treated most urgently and will be closed as soon as possible